Enquire about this Product

For more information please complete the form below or call us on 0115 927 4111.

Opening hours: Monday - Thursday: 9am to 5pm | Friday: 9am - 4pm

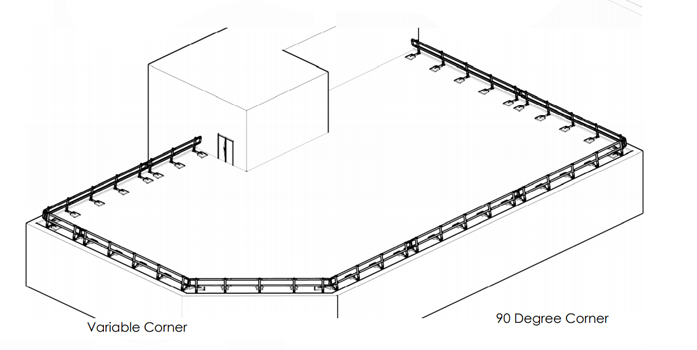

General Description

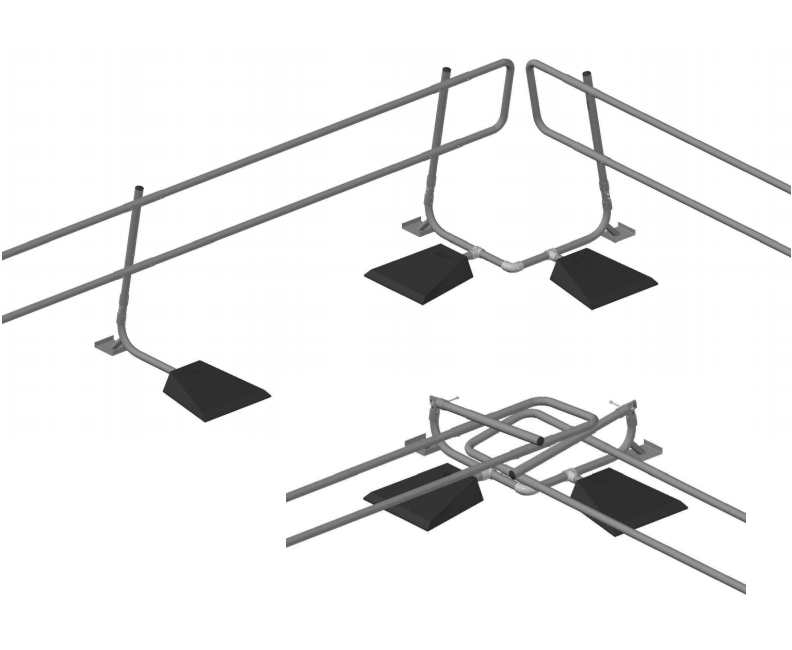

Our freestanding folding edge protection system is a cantilevered guardrail system that does

not require any mechanical fixing into the roof surface. This system has been designed and

manufactured to fully comply with current H.S.E regulations.

Material

The uprights are fabricated from 2mm hot dipped galvanised steel equivalent to BS EN ISO 1461,

with the upper and lower cross rails manufactured from 1.5mm x 48.3mm external diameter

galvanised steel.

The counterweight is manufactured from 100% recycled PVC compound with the fixing screws

manufactured from zinc-coated steel.

Safety Standards

Our freestanding guardrail is designed in accordance with and/or tested to the following safety

standards:

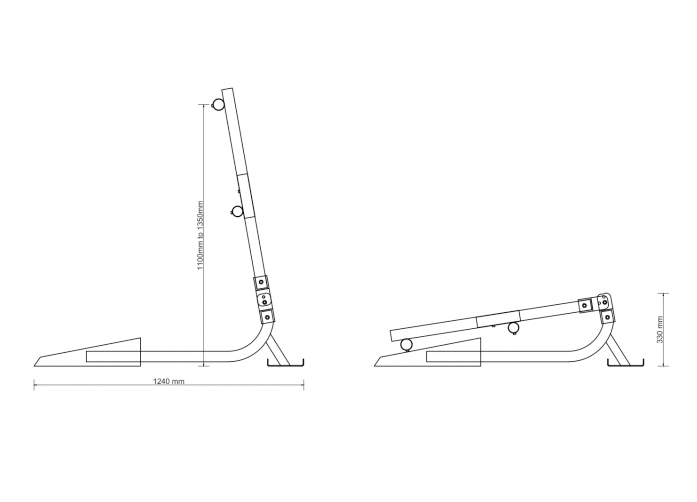

MSUP - Main Support Upright

The main upright sits on the roof and has a 20kg counterbalance weight attached, and the

adjustable top riser unit.

The foot of the upright which rests on the roof is protected by a rubber isolation pad. By

loosening the fixing screws in the body of the top riser, the unit can be moved up and down

the main upright to adjust the height of the top and middle rails or to raise and lower the main

upright.

The folding bracket has a fixed bolt and a removable D pin. When the pin is removed the top

section of the upright will fold down.

Materials

The main upright is manufactured from 2mm x 48.30mm steel tube, which has a hot dipped

galvanised coating. It is also available powder coated to any RAL colour.

Please note: The main upright shown here has a counterweight attached to help give the full dimensions

when installed. The counterweight is sold separately

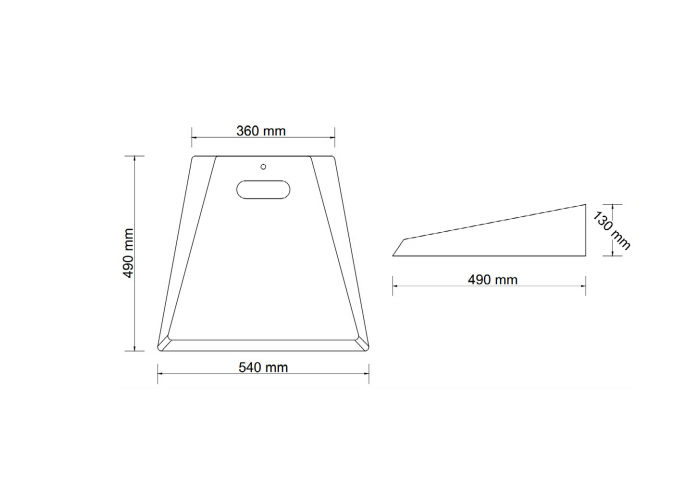

CW20 - 20kg Counterweight

The weight is designed to be attached to

each of the main uprights, and is fixed in

place with a small zinc coated grub screw

which provides the necessary counterbalance

weight to prevent the system from being

moved.

Materials

The 20kg weight is manufactured from 100%

recycled PVC compound.

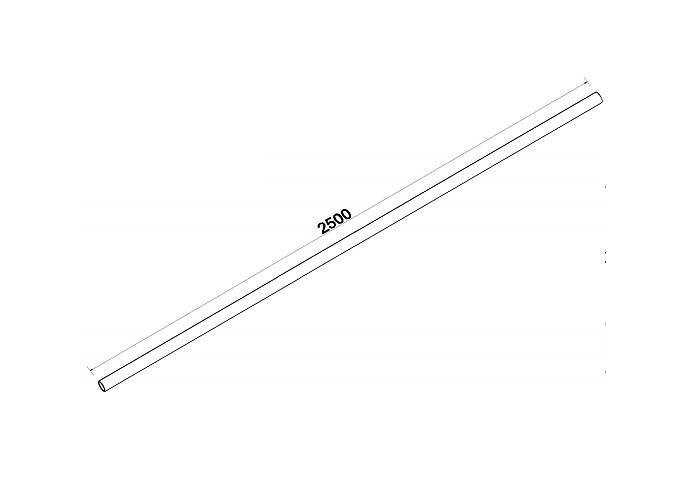

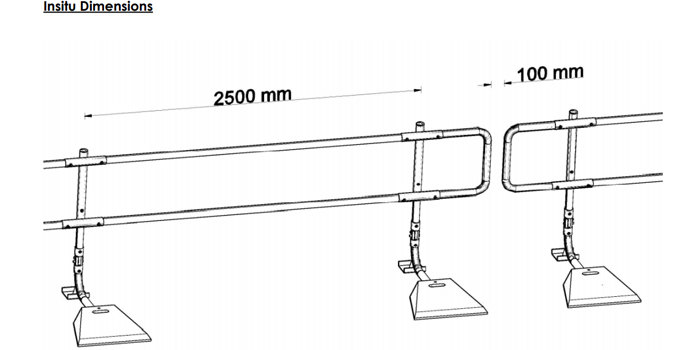

CR2.5 - 2.5m Cross Rail

The main cross rail is supplied pre-cut to 2.50m

in length for ease of installation. This fixed length

means there is no need to measure or cut the

tubes to ensure the uprights are spaced evenly.

Materials

The lightweight main rail is manufactured from

1.5mm light gauge steel making it easy to cut

and transport. It is galvanised coated to BS EN

ISO 1461 and is also available powder coated

to any RAL colour.

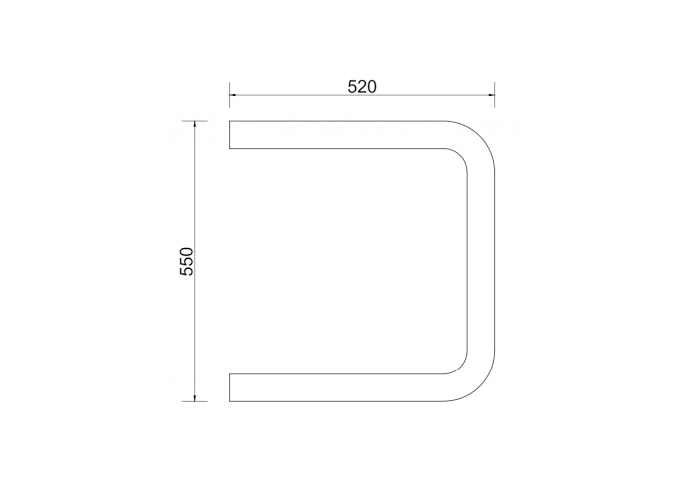

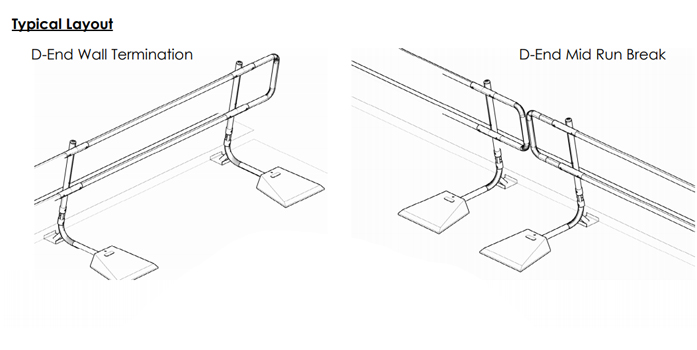

DE180 - D-End Termination

The pre-formed 180˚ bend inserts into the top

riser and is a quick and convenient way of

terminating a run of guardrail. This flexible

pre-formed component can be used for both

horizontal and vertical terminations.

Materials

The ‘D’ end is manufactured from 2mm steel

and is galvanised coated equivalent to BS EN

ISO 1461. Its is also available powder coated to

any RAL colour.

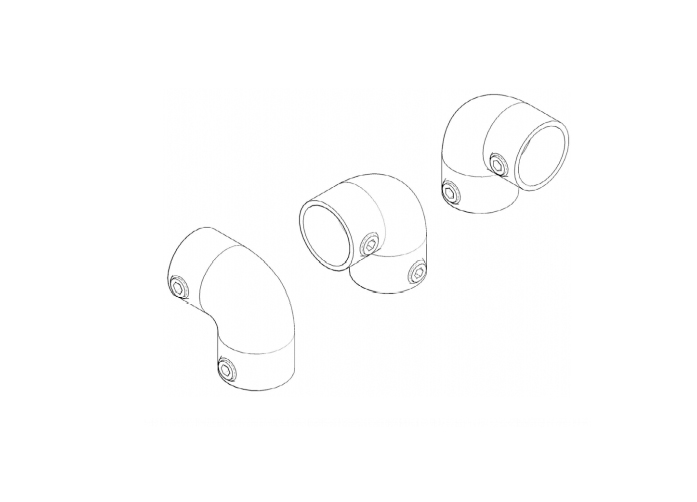

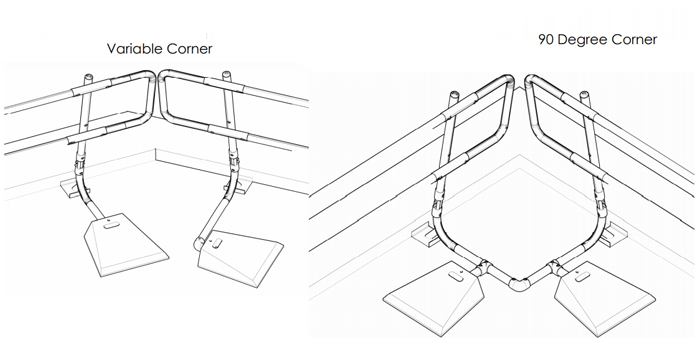

RC02 - 90° Elbow

The pre-cast 90˚ elbow allows for a

quick and convenient way of creating a

corner.

Materials

The 90 deg elbow is manufactured from cast

steel and is galvanised coated equivalent to BS

EN ISO 1461. Its is also available powder coated

to any RAL colour.

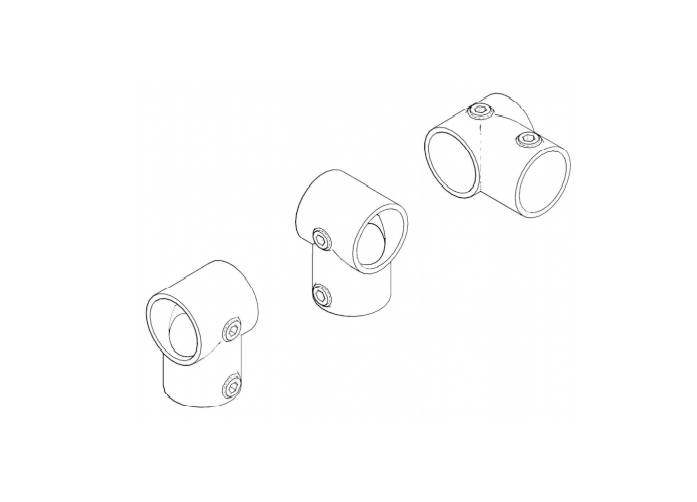

RC03 - Short Tee

The pre-cast short tee allows for a

quick and convenient way of creating a butt

joint.

Materials

The short tee is manufactured from cast steel

and is galvanised coated equivalent to BS EN

ISO 1461. It is also available powder coated to

any RAL colour.

Free Standing Folding Edge Protection - System Maintenance

The system is maintenance free, however if cleaning

is required, use only a mild detergent and water (such as

a domestic washing up liquid) in order not to damage

any of the galvanised coating.

Commissioning

Free Standing Folding Edge Protection - System Commissioning

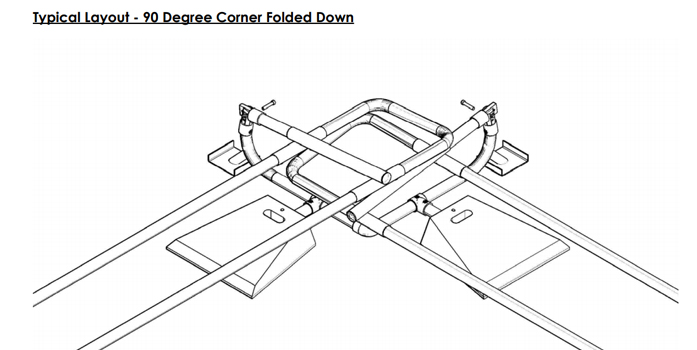

The rail can be folded down by 2 operatives. One should support the section at the centre of

the run. The second should remove the D pins (storing safely as they go along), starting from the

centre and working out towards the end termination. The rail should then be lowered safely and

steadily by 2 operatives.

To re-erect the rail, two operative should lift back to position. One operative then supports the

rail whilst the second operative replaces the D pins, starting from the centre and working out.

Re-Certification

Free Standing Folding Edge Protection - System Re-Certification

For more information please complete the form below or call us on 0115 927 4111.

Opening hours: Monday - Thursday: 9am to 5pm | Friday: 9am - 4pm